Steam Turbine Generators

Produce power from your process and reduce operating costs

Increase Overall Energy Efficiency and Reduce Costs

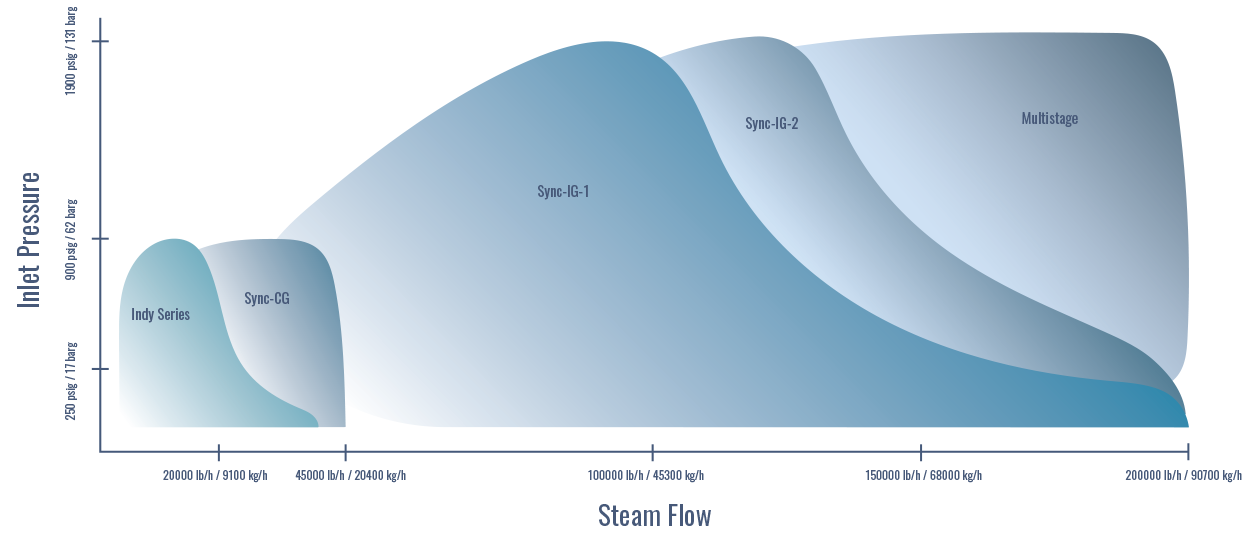

AirClean specializes in designing, packaging and installing steam turbine systems for industrial facilities. Use the following graph to help you find which series/model might be most applicable to your process.

In a steam turbine generator, steam is used to turn the wheel of the turbine, which can drive a generator (as in our Indy and Sync series units) or another piece of rotating equipment, such as a pump or a fan (as in our Mech series units). For more information, see below.

Indy Series STG’s

The Indy Series uses an induction generator directly coupled to a steam turbine. They economically produce between 100 kW and 1,250 kW and are ideal for small PRV bypasses in facilities looking to cut their power costs.

Sync Series STG’s

The Sync Series are a flexible and efficient option for many applications, from PRV bypasses to full plant island operation. Synchronous generators are coupled via gearbox to a steam turbine generator for maximum efficiency and power generation between 100 kW and 7 MW.

Mech Series STG’s

Mechanically drive your pumps, fans or other rotating equipment while efficiently letting down your steam pressure. The mech series can be sized for equipment starting at 50 hp and up to 9000 hp.

STG Controls

Our STG’s are all packaged with PLC-based control systems for easy operation and integration with distributed control systems. One button start-up and continuous monitoring mean that you can do your work while the STG takes care of itself.

Multistage

For some larger applications, a multistage turbine is the most economical option. If your application has especially high steam flows or available heat, please contact us to discuss whether a multistage turbine would be right for you.

Feel free to contact us whenever you are ready to discuss your project. We look forward to working with you!