Waste Heat Recovery Solutions

Reduce Operating Costs by Increasing Energy Productivity

A significant amount of excess heat generated in a variety of industrial processes is often wasted. Waste heat recovery refers to when heat that would otherwise be lost is captured and reused. Heat is typically recovered by converting water to steam which can then be used for a variety of applications, including space heating, absorption cooling, preheating furnace loads, mechanical drives and generating electricity.

According to the Department of Energy, studies have estimated that as much as 20 to 50% of industrial energy consumption is ultimately discharged as waste heat. Many industrial manufacturers can reduce these losses by improving equipment efficiency and installing waste heat recovery systems.

If you have waste heat, AirClean Energy help you put it to better use. Below are a few of the many applications which can benefit from heat recovery packages:

- Basic Oxygen Furnace

- Cement Kiln

- Clinker Cooler

- Steel Reheat Furnace

- Glass Furnace

- Incinerator

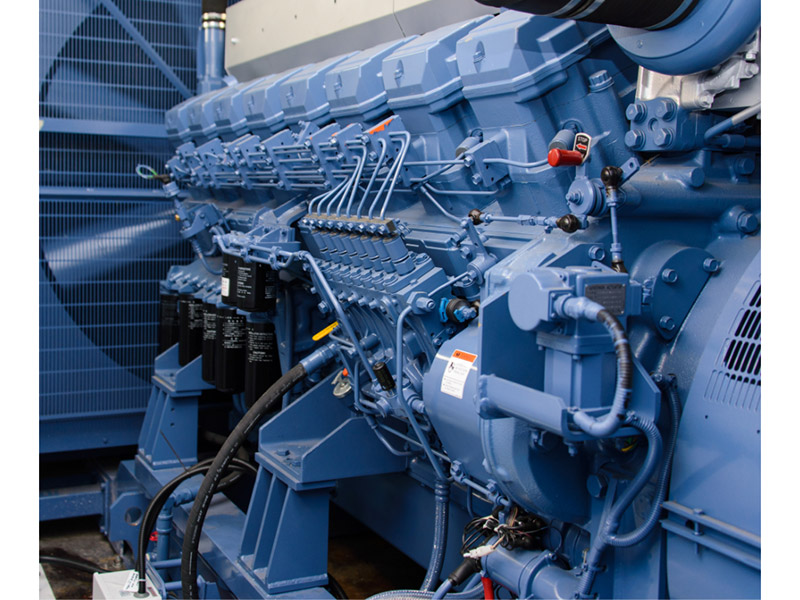

- Engine and Gas Turbine Exhaust

- Excess Thermal Oil

AirClean Energy can perform the engineering, design, and procurement of all equipment and processes for waste heat recovery systems. We deliver systems that provide effective and efficient waste heat recovery for a diverse range of industrial processes.